- Vegetable oil extraction machine manufacturer

- oilmachine@doingoilmachine.com

- Phone:008613526627860

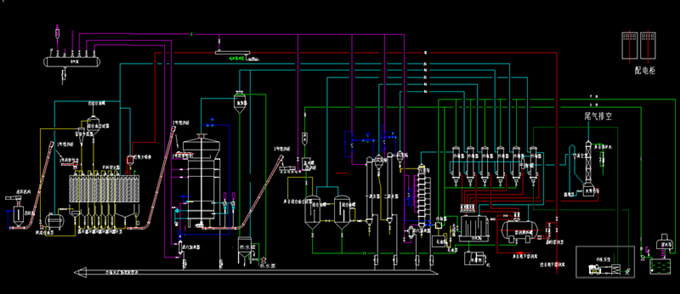

Sunflower cake solvent extraction machine photo

Sunflower cake solvent extraction machine is the second step in sunflower oil processing machine.Product (cake from sunflower oil press section) is carried into solvent extraction palnt.There are still much oil in cake.Solvent sprays onto cake so that cooking oil can be easily extracted. Then we can get high yield cooking oil .

Working principle of sunflower cake solvent extraction machine:

a. The peanut cake (for pretreatment) is sent to rotary extraction by the scraper conveyor. The crude oil will extracted by the solvent or mix oil. After this step, we will get meal and mix oil

b. Meal is send to toaster. Through the toaster, the solvent in the meal will seperate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

c. After the mix crude oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the crude oil is separated.

d.The mix crude oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Sunflower cake solvent extraction machine

Technical parameters of sunflower cake solvent extraction machine:

| 1 | Residual oil in meal | ≤ 1% (different from various oilseeds) |

| 2 | Solvent consumption | ≤1.5-3Kg/T (hexane) |

| 3 | moisture and volatile matter | ≤ 0.30% |

| 4 | Power consumption | ≤ 15KWh/T |

| 5 | Steam consumption | ≤280Kg/T (0.8MPa) |

| 6 | Finished meal moisture | ≤ 10-13% (adjustable) |

| 7 | Residual solvent in finished meal |

≤ 300PPM (qualified detonated experiment) |