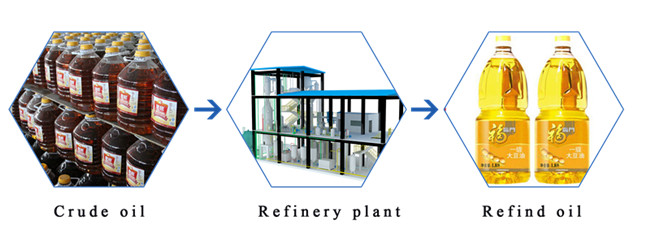

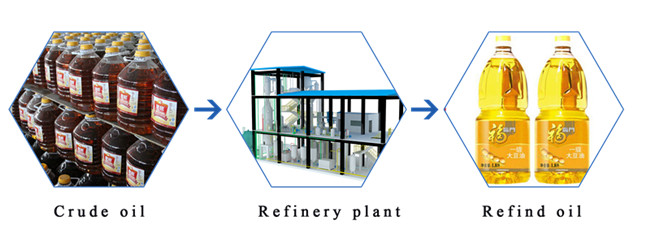

Semi-continuous crude oil refining machine

The semi-continuous crude oil refining machine design is based on batch type oil refining machine but higher than batch type.Compared with batch type oil refining production line, semi-continuous crude oil refining machine is more efficient. At the same time compared with fully continuous crude oil refining machine, Semi-continuous crude oil refining machine needs less investment cost. The semi-continuous crude oil refining machine capacity can be designed according to customer requirement. It’s suitable for the middle type oil refining machine from 10TPD to 50TPD. So it is also called middle scale crude oil refining machine.

Semi-continuous crude oil refining machine

Raw material of semi-continuous crude oil refining machine:

The semi-continuous crude oil refining machine has widely scope of raw materials. It can deal with different kinds of oil.

Vegetable seed oil: cottonseed oil, sunflower seed oil, soybean oil, peanut oil, palm oil, coconut oil, chiaseed oil, etc.

Fruit oil: Grape seed oil, palm fruit oil, olive oil, avocado oil, etc.

Animal oil: Fish oil, seal oil, etc.

Semi-continuous crude oil refining machine introduction:

Semi-continuous crude oil refining machine has a main process which is different from batch type: that is deodorization.

Crude edible oil refining process machine

Deacidification/ Neutralization: Use NaOH to react with FFA inside oil. Then the reaction product soap stock will be discharged.

De-gumming: Use hot water to mix with crude oil to remove the gum inside oil. Then dry the oil for bleaching process.

Decoloration/Bleaching: Use the bleaching earth to take the impurities out. Then use the filter to remove the bleaching earth.

Deodorization: This is the main different type from batch type oil refinery. It’s continuous type. We use the continuous deodorization tower to remove the peroxide value. Then there will be no serious smell in edible oil. After filtering, you will get final oil product.

Functions of main parts in semi-continuous crude oil refining machine:

Refining section: used for P-acid de-gumming, alkali refining de-acid and water rinsing.

Decoloring section: used to remove pigments, bleaching oils and grease dehydrate.

Deodorizing section: to remove the odor components off oil.

Dewax: used to remove the wax off the oil, in order to get the high quality oil.

Heat-transfer oil stove: supply each device that needs heat energy; temperature can reach above 280°C.

Steam generator: produce steam for de-odoring and distillation.

Vacuum pump: supply vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

Press filter: filter clay, filter out clear oil.

Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

Sample projects of batch type oil refinery process machinery:

|

|

|

1tpd crude oil refining machine |

2tpd crude oil refining machine |

|

|

|

5tpd crude oil refining machine |

10tpd crude oil refining machine |